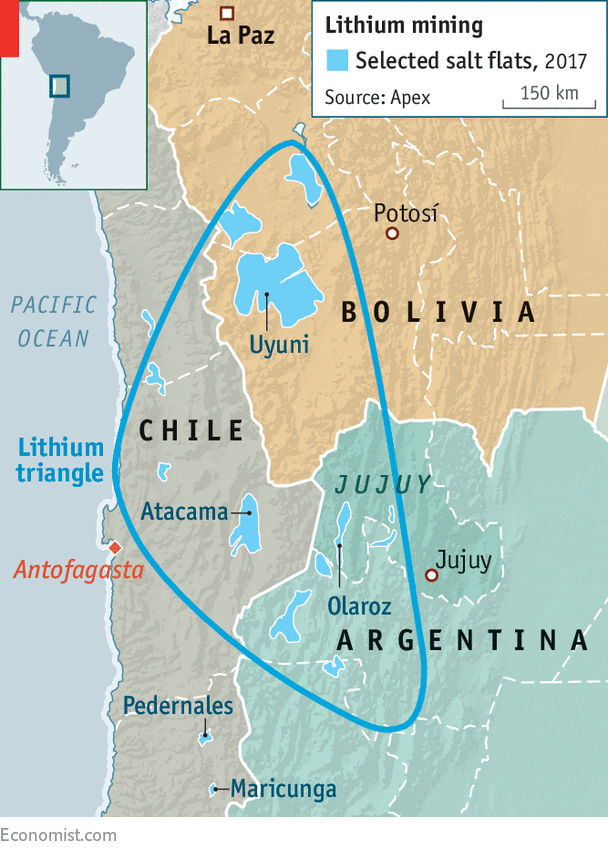

Extraction of lithium from brine consists of a series of physical and chemical reactions for a final product that contains lithium. Brines are essentially large lakes or ponds that occupy thousands of acres and that contain a variety of minerals and rocks. These brines occur naturally in different parts of the world, with a high recurrence in South America, where Argentina, Bolivia, and Chile all congregate to form what is known as the “Lithium Triangle”.

Lithium extraction from brine consists of a series of evaporation and solid-liquid separation methods. Different techniques are employed, but the standard practice is as follows:

- The brine, which contains lithium among other dissolved minerals, is initially pumped into large, shallow ponds. Here, it is subjected to continuous solar heat, which gradually evaporates the water content. This evaporation process is extensively slow, typically requiring upwards of a year to complete, depending on climatic conditions. The objective is to progressively concentrate the dissolved minerals as the water volume decreases.

- Evaporation continues until the lithium concentration within the brine reaches approximately 6,000 milligrams per kilogram (mg/kg). At this concentration level, lithium makes up about 0.6% of the brine’s total mass (considering that 10,000 mg/kg would correspond to 1% of the mass). This specific concentration is targeted to optimize the efficiency of subsequent purification steps.

- Following evaporation, the next phase is the solid-liquid separation process. This is primarily achieved using slaked lime (calcium hydroxide, Ca(OH)₂), which is introduced to the concentrated brine to precipitate calcium-based compounds and other non-lithium constituents. The slaked lime reacts with soluble impurities to form insoluble precipitates, which are then mechanically separated from the lithium-rich liquid.

- The lithium-enriched brine is then transferred to a processing facility designed to further purify the product. At this stage, advanced techniques such as filtration, solvent extraction, and ion exchange are employed. Additionally, specific reagents may be added to refine the lithium concentration and remove residual impurities, thereby enhancing the overall purity of the lithium.

- The highly purified lithium product is subjected to two distinct chemical processes to convert it into commercially valuable forms:

- Lithium Carbonate Production: The purified brine is treated with soda ash (sodium carbonate, Na₂CO₃), which precipitates lithium carbonate (Li₂CO₃), a white powder that serves as a primary industrial and pharmaceutical lithium compound.

- Lithium Hydroxide Production: Alternatively, the processed brine can be further treated to produce lithium hydroxide monohydrate (LiOH·H₂O), through a method that adjusts the lithium’s chemical structure for use in more specific applications, such as in high-performance lithium-ion batteries.

Despite continuous developments in the evaporation and solid-liquid separation (or purification) processes, the recovery rate of lithium from brine operations typically caps at about 50% of the original lithium content in the native brine. According to a 2019 report by S&P Global Market Intelligence, the average production cost for these operations is approximately 5,580 USD per metric ton of LCE.